What does a chemical engineer do?

Overview

Energy & fuels

(like oil, natural gas)

Agricultural chemicals

(like fertilisers)

Synthetic fibres

(like nylon, polyester)

Exciting new areas

Nanotechnology

Alternative energy

(like fuel cells)

Biotechnology

Functions of a chemical engineer

Design

In this virtual tour you will understand how a chemical engineer designs chemical production process by working on similar engineering assignments.

Supervise

In this virtual tour you will understand how a chemical engineer supervises chemical production by working on similar engineering assignments.

Note: Assignments are quite simplified compared to real work so that high school students can solve them

Tour Compatibility: Tours can be viewed well only on laptops/desktops and not on mobile phones currently.

What will I study in chemical engineering?

Fluid Mechanics

Study of fluids (liquids, gases) at rest and in motion, and the forces involved

Practical example

Fluid systems in aircrafts, pumps, brakes

Related high school topics

Pressure in fluids, streamline flow, Bernoulli’s principle, viscosity, Reynolds number, surface tension

Thermodynamics

Study of heat and temperature and their relation to energy and work

Practical example

Coffee-maker, air-conditioner

Related high school topics

Thermal equilibrium, heat, internal energy, work, laws of thermodynamics, specific heat capacity, thermodynamic state variables & equation of state, heat engines,refrigerators, heat pumps, Carnot engine, enthalpy

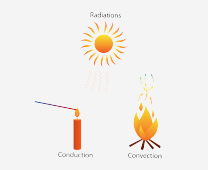

Heat Transfer

Study of exchange of thermal energy between physical systems

Practical example

Coffee-maker, air-conditioner

Related high school topics

Temperature & heat, thermal expansion, specific heat capacity, calorimetry, change of state, Newton’s law of cooling

Pre-requisites

Understanding of below concepts and equations (wherever mentioned) is required

Reaction stoichiometry

Relationship between quantity of reactants and products given by a balanced chemical reaction.

Example:

CH4 + 2O2 -> CO2 + 2H2O

As per above reaction, one mole of CH4 reacts with two moles of O2 to give one mole of CO2 and two moles H2O

Molar mass

Mass of one mole of a substance. It is generally in g/mole.

Example: molar mass of water is 18 g/mole

Distillation

Distillation is separation of components from a mixture based on difference in their boiling points. It involves selective evaporation and condensation.

Volume of right cylinder

V = πr2h

(where V = volume, r = radius, h = height)

Pre-requisites

Understanding of below concepts and equations (wherever mentioned) is required

Crystallization

Crystallization is a process that separates a pure solid in the form of its crystals from a solution.